Description

Stop Log – Efficient Water Flow Control for Canals and Locks

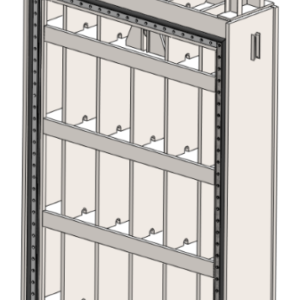

Stop logs are steel partitions used in canals or control structures to effectively retain the flow of water. They are lowered individually one on top of the other via a vertical guiding system to a predetermined height, allowing precise adaptation to the dimensions of the lock where they restrict the water flow. The design of stop logs is a unique rectangular unit that can be used in a simple or modular format to retain different volumes of water flexibly and efficiently.

Generally, stop logs are carefully designed and manufactured to achieve the most effective modular increments, thus meeting the specific requirements of the particular site where they will be installed. They offer a robust and highly adaptable solution for various water management applications.

These types of logs are made of steel plate, appropriately reinforced with various steel sections to withstand significant water pressures, ensuring their exceptional durability and performance in demanding environments.

Versatile Operating Systems:

A lifting beam, as part of a lifting system, ensures the raising and lowering of the stop logs in their guides to reach the required height. The special operating system is defined and agreed upon with the client.

Possibility to provide a complete set of accessories:

- Bypass system;

- Lifting system (cranes or different equipment);

- Original spare parts;

All phases of technical design and manufacturing up to final testing are carried out by Vortex Hydra in accordance with the UNI EN ISO 9001 quality management system.

Range of applications from Vortex Hydra:

- Wide range of dimensions with no limitation in width and height

- Water flow control in canals and control structures

- Adaptation to the dimensions of locks

- Civil engineering and adaptation to specific site conditions

- Lifting systems for raising and lowering

- Closing maneuvers in unbalanced conditions

- Integrated bypass systems

- Applications with no limitation in width and height

MAIN MATERIALS

| Component | Proposed Material |

|---|---|

| Main structural elements, Plate, Steel profiles, Gate frame | S355J2G3 EN 10025 (or equivalent) |

| Flange, Upper frame cover, Bars, Anchoring, Integrated parts | |

| Seat joint | AISI 316 (or equivalent) |

| Seals | Neoprene rubber (or equivalent) |

| Bolts for joint fixing | A2-70 (or equivalent) |

Flexible and Custom Design Solutions:

- The dimensions of the stop logs can be modified to adapt to the existing site conditions or the special design required by civil engineering works;

- Sealing system: rubber at the bottom, top (if necessary), and on the lateral sides of each stop log element, metal housing (stainless steel counter seat fixed to the concrete frame);

- The stop logs can also be equipped with fixed side rollers in case it is necessary to perform closing maneuvers in unbalanced conditions;

- They are normally equipped with an integrated bypass system operated by the lifting beam, which allows them to be raised in balanced conditions, limiting the lifting system's capacity.