Description

Roller Gate – Advanced Water Flow Control for Plants and Channels

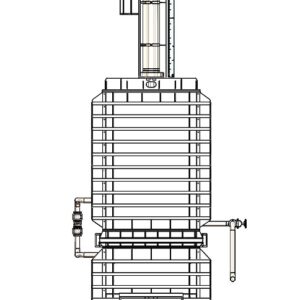

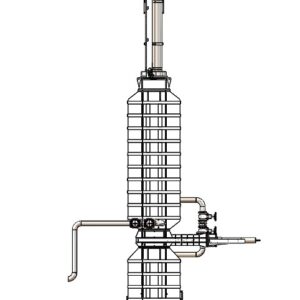

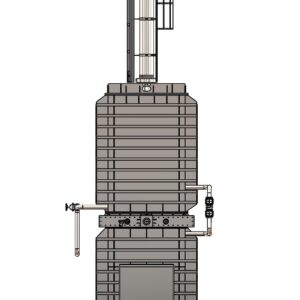

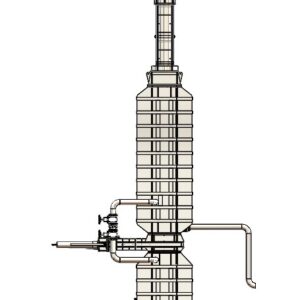

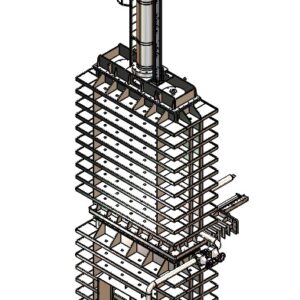

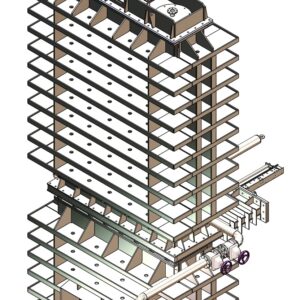

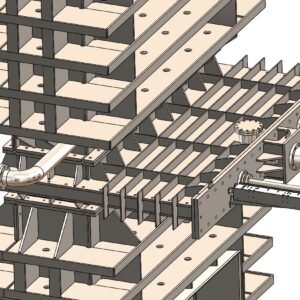

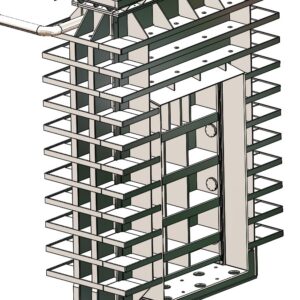

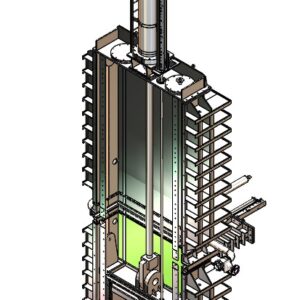

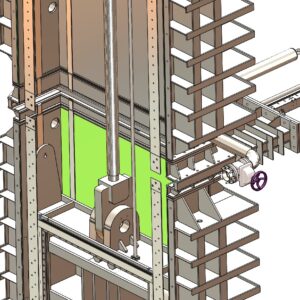

The roller gate is an essential piece of equipment for controlling water flow and providing flood protection, primarily used in water treatment plants and open water channels. Constructed from reinforced steel plate with rubber and stainless steel seals (AISI 316 or equivalent), the roller gate is designed to withstand high water pressures and ensure effective sealing. Highly adaptable, the roller gate can be customized to meet specific site conditions.

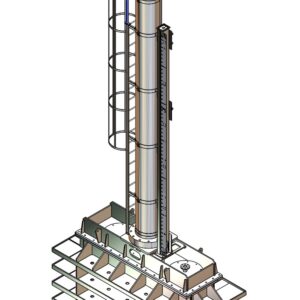

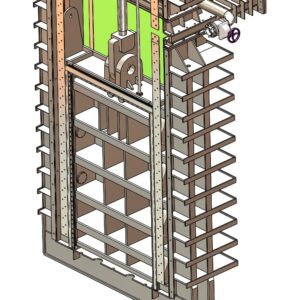

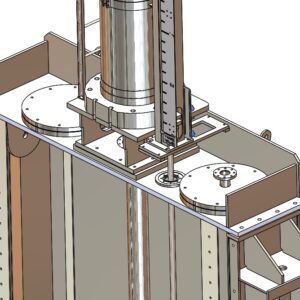

The roller gate features versatile operating systems, including single and double-acting hydraulic cylinders, as well as an electric motor with a reducer. Robust rollers facilitate the opening and closing operations even under imbalanced conditions.

Available accessories for the roller gate include diversion systems, hydraulic units, electrical cabinets, and original spare parts. The design, manufacturing, and final testing of the roller gate are conducted in accordance with UNI EN ISO 9001 standards. The main materials used in the construction of the roller gate include S355J2G3 EN 10025 steel for structural components, neoprene rubber for sealing, and A2-70 bolts for joint fixation. The roller gate can be manufactured in a wide range of dimensions, without limitations on width or height.

The adaptability and robustness of the roller gate make it an ideal solution for various water control applications. Whether in a water treatment facility or an open channel system, the roller gate provides reliable performance and durability. With its flexible design and high-quality materials, the roller gate ensures efficient and long-lasting operation, making it a key component in modern water management infrastructure.

Versatile Operating Systems :

- Single-Acting Hydraulic Cylinder: Opening by pressurized oil and closing by gravity;

- Double-Acting Hydraulic Cylinder: Opening and closing by pressurized oil;

- Electric Motor Coupled with Reducer and Vertical Rod;

- Special Operating System Defined and Agreed Upon with the Client

Possibility to Provide a Complete Set of Accessories:

- Bypass System

- Hydraulic Unit

- Electrical Cabinet

- Original Spare Parts

All phases of technical design, engineering, and manufacturing, including detailed assessments and rigorous final testing, are meticulously carried out by Vortex Hydra. This process is conducted in strict accordance with the UNI EN ISO 9001 quality management system, ensuring that every aspect of the slide gate meets the highest standards of quality and performance. Vortex Hydra’s commitment to excellence ensures that each slide gate is thoroughly evaluated and perfected to deliver optimal functionality and reliability.

- Provide a vertical water barrier

- Water treatment plants

- Pressurized systems

- Open channels

- Flood protection

Main Materials

| Component | Proposed Material |

|---|---|

| Main structural elements: plate, steel profiles, gate frame, flange, top frame cover, bars, anchorage, integrated parts |

S355J2G3 EN 10025 (or equivalent) |

| Seat seal | AISI 316 (or equivalent) |

| Seals | Neoprene rubber (or equivalent) |

| Bolts for joint fixation | A2-70 (or equivalent) |

Flexible and Custom Design Solutions:

- Valve dimensions can be modified to fit existing site conditions or special designs required by civil engineering works;

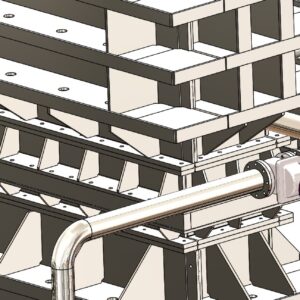

- Sealing system: rubber at the bottom, top (if necessary), and on the side edges, with a metal housing (stainless steel seat seal fixed to the concrete frame).

- For the wagon type, the design includes robust rollers capable of withstanding water loads and allowing for opening/closing maneuvers even under unbalanced conditions by reducing friction resistance;

- Stainless steel seat seal on the side, bottom frames, and lintels, partially embedded in civil engineering works;